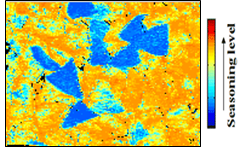

One of the early projects that sparked the incorporation of ProSensus in 2004 was a machine vision application for the foods industry. In this case, multivariate image analysis was used to implement online monitoring and control of the seasoning level of a snack-food for Frito-Lay.

Since that time, food quality and food safety have continued to be important applications that ProSensus increasingly supports across all three of our service areas which are: Product Development, Process Analysis, and Machine Vision.

ProSensus generally offers consulting and software for product development, consulting and training for process analysis and turnkey solutions for machine vision.

Product Development

In the foods industry, new product development can be driven by consumer complaints or changing consumer trends (in areas such as flavor and nutritional value) or by the introduction of new or tighter food safety compliance criteria (such as thresholds on key Attributes of Interest (AoI)). These driving forces may lead product development efforts to slightly adjust existing products or to develop entirely new products.

Recognizing the potential value in their R&D data, food manufacturers have implemented connectivity tools and software to extract, organize, and store the data from lab and manufacturing instruments. Now, the foods industry is ready to begin intelligently using this data, such as through the application of multivariate modeling (MVA) and numerical optimization.

Some of the benefits of performing MVA and optimization on product development data include:

- Accelerated product development timelines

- Time and cost savings for physical experiments

- Ability to efficiently address food safety regulations and customer complaints

- Increased R&D knowledge retainment & broader resource capacity

Case Study: Muffin Batter Reformulation

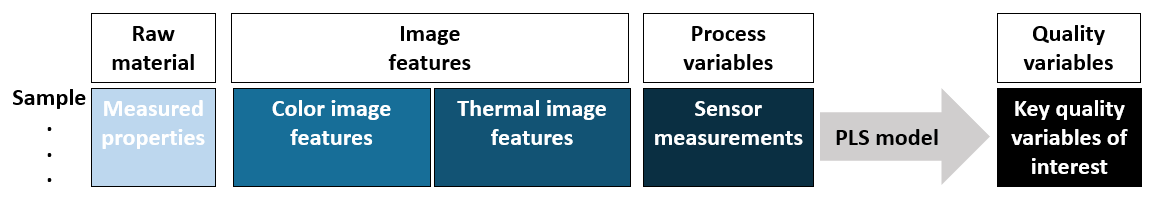

ProSensus developed a multi-block PLS model for a product development application aimed at reducing an undesirable quality attribute in an existing frozen muffin batter formulation without introducing new ingredients and while maintaining sensory properties. Read the case study for further details.

ProSensus developed a multi-block PLS model for a product development application aimed at reducing an undesirable quality attribute in an existing frozen muffin batter formulation without introducing new ingredients and while maintaining sensory properties. Read the case study for further details.

Process Analysis

As consumers worldwide prioritize health and nutrition, while regulatory agencies demand accountability for food-related illnesses, today’s food manufacturers require advanced analytics to demonstrate their commitment and compliance to the highest quality and food safety standards.

Food manufacturing process contain a variety of process conditions and product properties that must be monitored, for example:

- Ingredient quantities and qualities

- Processing temperatures (such as baking or frying temperatures, pasteurization, etc.)

- Final quality properties (such as ingredient distributions, contaminant or undesirable AoIs, etc.)

- Product packaging requirements and storage conditions (such as minimum cold storage temperatures, etc.)

Analytics can be used to implement real-time monitoring, prediction, optimization, and control on food manufacturing processes with advanced analytics. For example, ProSensus has expertise in developing latent variable models that are deployed as soft-sensors to reduce off-spec production and reliance on intermittent (and time-consuming) lab measurements by predicting an otherwise difficult-to-measure quality variable.

Case Study: Batch Frying of Snack Foods

ProSensus’ process analysis work helped improve the product quality and plant productivity by implementing batch closed-loop model predictive control on batch fryers. Find all the details in the complete case study.

ProSensus’ process analysis work helped improve the product quality and plant productivity by implementing batch closed-loop model predictive control on batch fryers. Find all the details in the complete case study.

Machine Vision

As higher imaging resolutions and rates become available, while at the same time camera pricing is dropping and image processing techniques are improving, there is more opportunity for machine vision applications in the foods industry.

ProSensus’ custom machine vision systems employ a variety of technologies including color, thermal, 3D, and polarized imaging to detect key food quality attributes.

Our solutions allowing our clients to:

- Quantify & log product quality

- Achieve 100% real-time inspection & automatic rejection

- Optimize processes to improve product quality and reduce off-spec product

- Increase customer satisfaction

- Gain new process insights

Case Study: Snack Food Seasoning Monitoring

ProSensus developed the image processing algorithms for an online color machine vision system that monitors and controls the seasoning of snack-foods. Learn more about this project.

ProSensus developed the image processing algorithms for an online color machine vision system that monitors and controls the seasoning of snack-foods. Learn more about this project.

Case Study: Benchtop Analyzer

ProSensus delivered a custom offline machine vision system that calculates advanced analytics of baked goods from a pilot plant using color imaging. This case study discusses product quality metrics that can be extracted by this system, as well as several use-cases for this system.

ProSensus delivered a custom offline machine vision system that calculates advanced analytics of baked goods from a pilot plant using color imaging. This case study discusses product quality metrics that can be extracted by this system, as well as several use-cases for this system.

Case Study: Multi-Camera Food Monitoring

Finally, ProSensus’ custom online machine vision system employs color and thermal imaging to monitor and calculate advanced analytics of baked goods from a full-scale production line. A sample HMI and description of all hardware components included in this system are presented in this case study.

Finally, ProSensus’ custom online machine vision system employs color and thermal imaging to monitor and calculate advanced analytics of baked goods from a full-scale production line. A sample HMI and description of all hardware components included in this system are presented in this case study.

Getting Started

Ready to advance your food manufacturing business? Contact us today to request an introductory meeting with ProSensus.