Climate change and climate awareness continue to drive increasingly comprehensive reporting requirements and restrictive limits related to air quality and pollution, as well as to water and energy consumption, for the manufacturing sector worldwide.

Long-term & Short-term Sustainability

Many companies are working towards long-term solutions such as making physical changes to their plants in order to make use of “clean” energy sources. However, planning and implementing these changes are not trivial tasks, and as a result, many manufacturers are looking for quick improvements that can be made in order to address sustainability initiatives in the short-term.

Analytics have long been applied to a variety of industrial datasets in order to achieve traditional manufacturing goals such as maximizing throughput or optimizing product quality. However, sustainability initiatives often compete with these traditional goals. Fortunately, MVA is capable of identifying process conditions that achieve multiple goals.

How MVA Can Help

Let us consider the illustrative example of wanting to minimizing energy consumption while maintaining a previously maximized throughput and optimized product quality.

ProSensus typically employs AspenTech’s ProMV to conduct analyses and implement monitoring models, such as below, on behalf of our clients as consulting services.

PLS Modeling

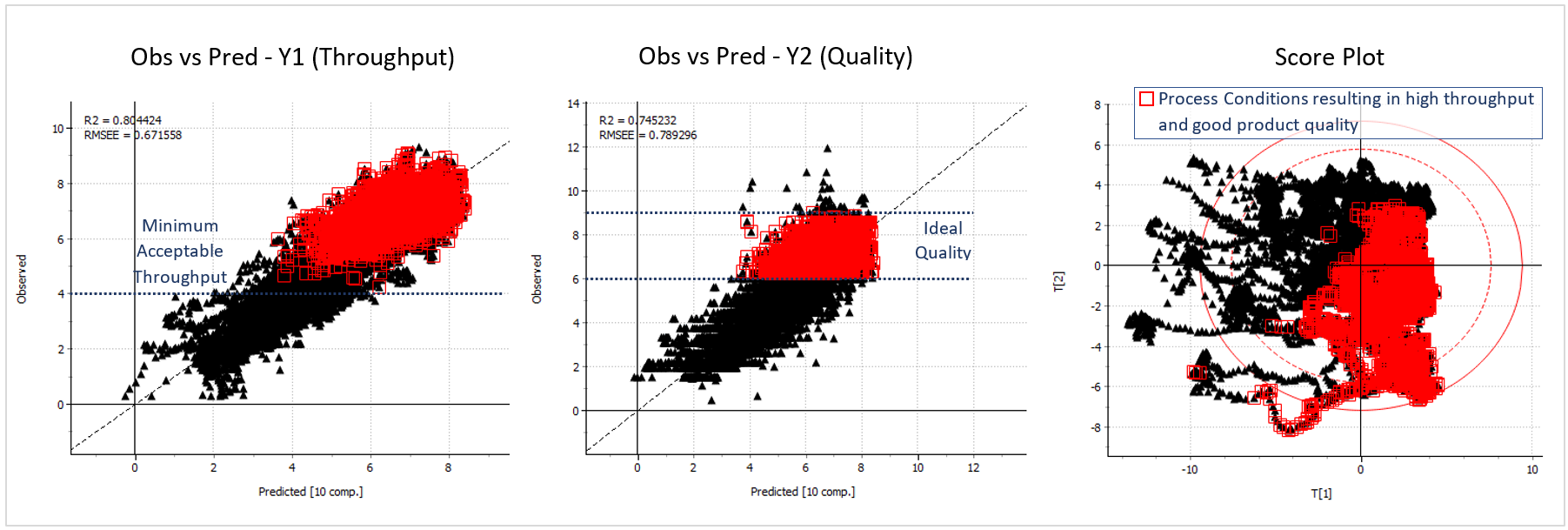

Starting from the beginning of this challenge, prior to the energy consumption initiative, a PLS model was originally developed to understand the process conditions (X) that result in both the throughput (Y1) and product quality (Y2) targets. This model is summarized by the observed versus predicted plots and score plot below, with acceptable operation identified in red.

Interpretation of various MVA plots from this model (such as contribution and coefficient plots, as well ProMV Model Optimizer results) allowed for a deeper understanding of key relationships and the ability to run this operation at a maximized throughput and optimized product quality.

Defining Energy Consumption

To address the newly added goal of minimizing energy consumption while still maintaining throughput and product quality, a real-time measure of energy consumption must first be defined and then computed for each point in time in the historical operation. ProSensus has familiarity with these types of calculations, however input from the subject-matter experts can be helpful in order to identify relevant theoretical and/or empirical relationships for the specific application.

PCA Modeling

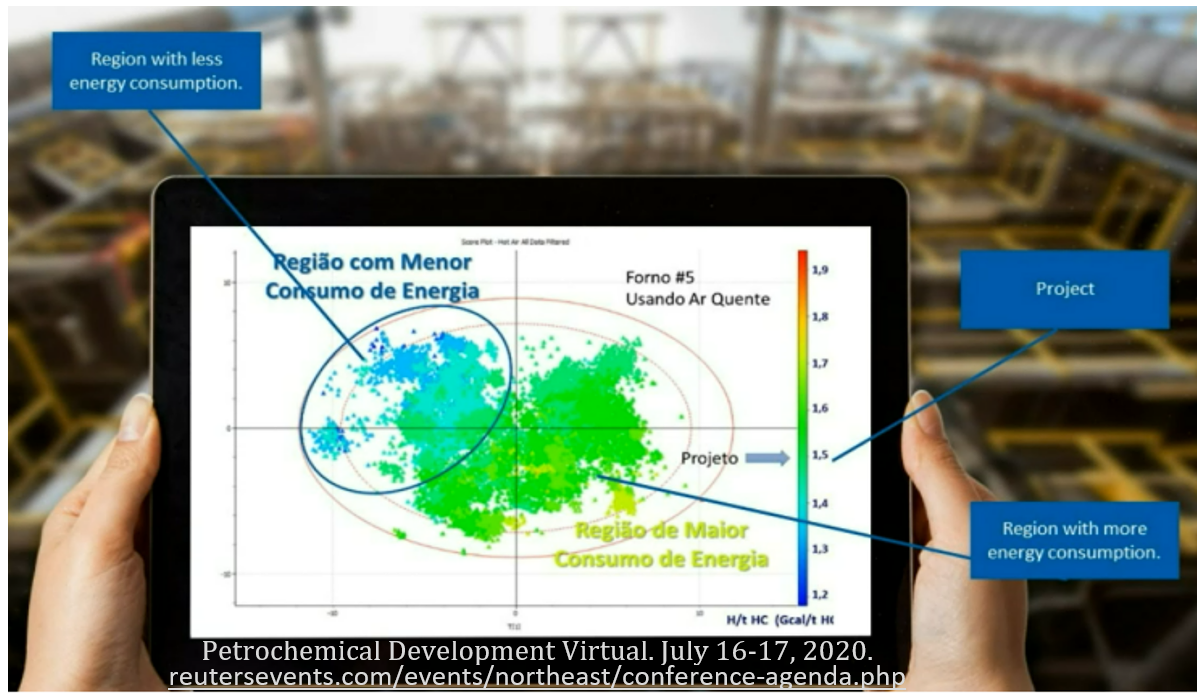

Next, a PCA model is built on the subset of observations that have resulted in both acceptable throughput and product quality.

The score plot of this model can then be used to readily identify regions (process conditions) that are associated with more or less energy consumption.

Monitoring and Control

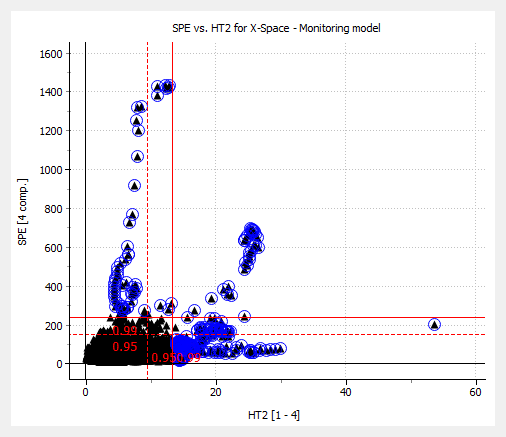

Finally, multivariate statistical process control (MSPC) can be implemented by developing a further refined PCA monitoring reference model on the subset of observations that are located in the energy efficient region of the score plot above.

Finally, multivariate statistical process control (MSPC) can be implemented by developing a further refined PCA monitoring reference model on the subset of observations that are located in the energy efficient region of the score plot above.

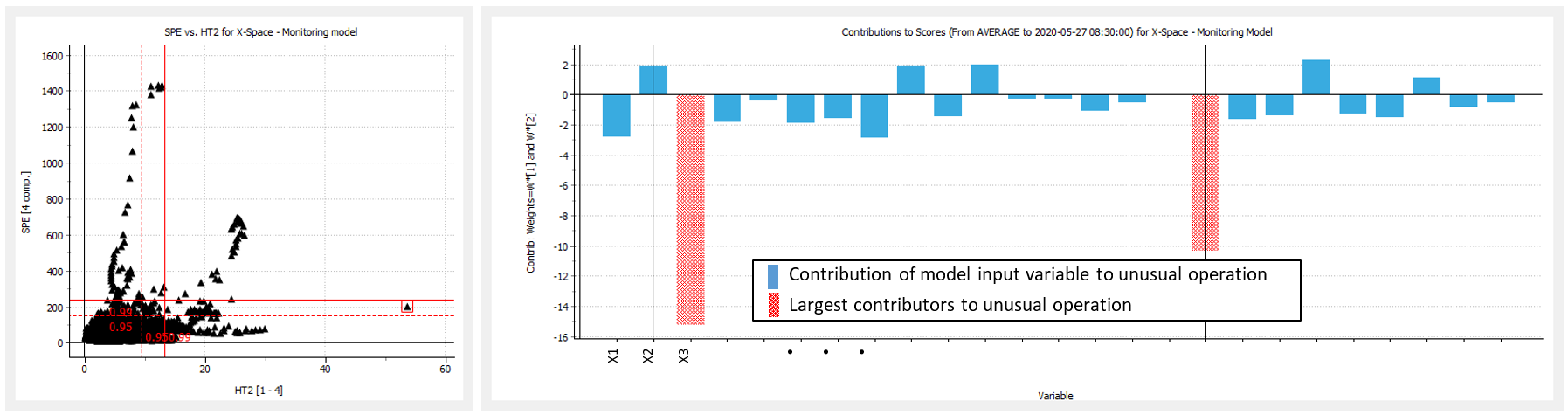

The HT2 and SPE model validity metrics of this final PCA model can be used to monitor the process for deviations outside the ideal operation, alerting operators of the need for corrective action to quickly return to the energy efficient zone.

Troubleshooting

A contribution plot can be used to readily identify the key sources of variation for a specific observation as well as the potential corrective actions.

Achieve Your Sustainability Goals with ProSensus

The above is only one simple example of how MVA can be used to achieve a sustainability goal while maintaining traditional manufacturing targets. Contact ProSensus to discuss your challenges and to learn more about how ProSensus can help.

References

- Petrochemical Development Virtual. July 16-17, 2020. Accessed on August 25, 2021 from https://reutersevents.com/events/northeast/conference-agenda.php