Titanium dioxide (TiO2) is commonly used across many industries such as paint & coatings, pharmaceuticals (capsules/tablets coatings), and food (additive and whitening pigment).

Titanium dioxide (TiO2) is commonly used across many industries such as paint & coatings, pharmaceuticals (capsules/tablets coatings), and food (additive and whitening pigment).

However, rising prices and growing concerns about its environmental impact are pushing formulators to seek out TiO2 alternatives to save cost and meet sustainability initiatives.1

European regulators have announced plans to classify TMP (a common surface treatment use for 90% of TiO2 formulations2) as a reproductive toxicant. Regulators have made their intentions clear that manufacturers should plan to eliminate TiO2 from product formulations.

The Role Of AI in TiO2 Reformulation Work

While there are some TiO2 alternatives on the market, the lower cost and more sustainable options typically come with a trade-off on opacity properties. Coatings experts still have a lot of work to do before this harmful chemical can be completely removed. Effective use of AI can accelerate this reformulation initiative. In fact, 69% of companies’ digital initiatives focus on environmental programs.4

The FormuSense approach is shown in an example dataset further in this article. Our proven approach follows a well established methodology that includes:

- DATA VERIFICATION by ensuring suitable variation exists and correcting data errors and emissions

- CALCULATE MIXTURE PROPERTIES using applicable mixture rules and the formulation ratios and ingredient properties

- MODELING the data and validating the resulting correlations modeled with domain experts

- SIMULATING the results of digital formulations before any material is physically made in the lab/pilot plant

- MATHEMATICAL OPTIMIZATION to create new candidate formulations by entering targets and constraints

This framework enables formulators to optimize the characteristics of their product quickly, while meeting growing regulatory and sustainability requirements.

How much can YOU decrease TiO2 by?

Run your own digital simulations to find out! Using a published dataset1 that used three TiO2 replacements, ProSensus has developed a predictive model with an R2 ~ 80% for four key paint properties. (Density, Whiteness, Gloss, Scrub Resistance)

Download our FormuSense model file to formulate your own coatings blend with less TiO2

![]() TiO2 Prediction for Architectural Paints (zipped FormuSense file)

TiO2 Prediction for Architectural Paints (zipped FormuSense file)

New to FormuSense? Activate a free 30-day trial to access the TiO2 model file.

Paint Formulation

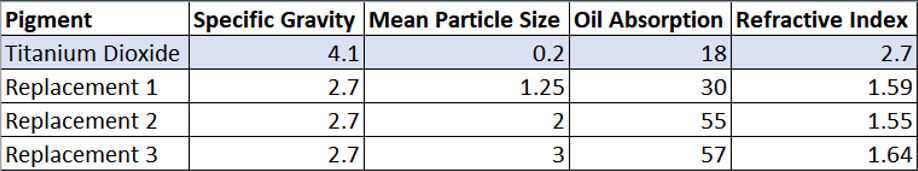

Architectural paints are generally composed of 5 basic components (binder, pigments, fillers, additives and dispersing medium). TiO2 is one of the main pigments used in the paint industry. In this dataset, multiple replacements were assessed after considering their impact on the final paint performance. Properties were measured on these replacements to help characterize their opacity performance as seen in the table below.

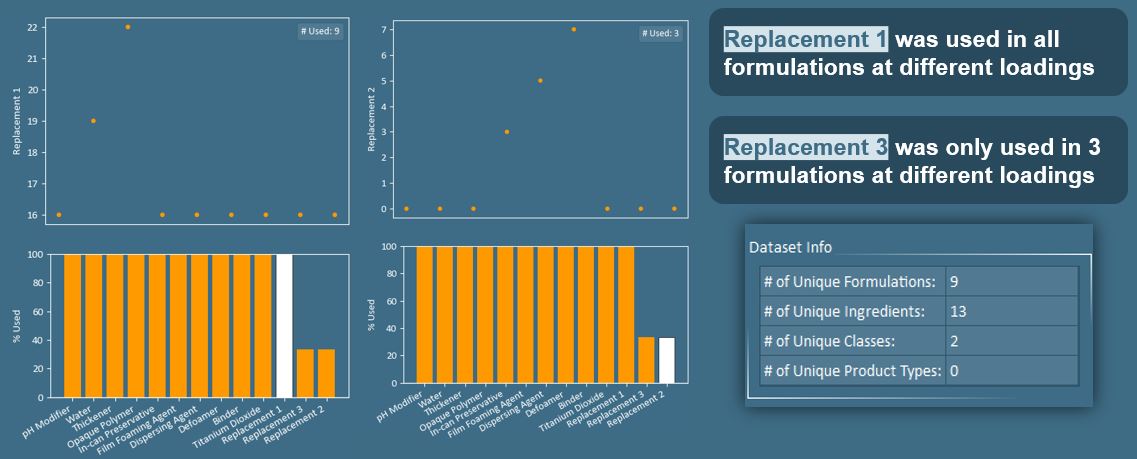

The paint formulation in this dataset had a consistent recipe for all components except for the pigment component. Three replacements were assessed at different loadings and combinations with a total of nine experiments for the analysis. While this is a small dataset, following the FormuSense approach can certainly help assess the results and design further experiments.

Import (Dataset Assembly)

The “Import” feature in FormuSense is well suited for formulations where two graphical summaries (raw data and % usage) of the ingredient ratios are generated to better understand the experimental design space.

FormuSense can be used to calculate mixture properties. These mixture properties are advanced input features that improve the model’s predictive ability and allow new unused ingredients to be considered in future formulations. In this example, the ideal mixing rule was used to calculate the mixture properties for the pigment ingredient class.

Predict (Model Building)

Although this dataset is quite small with only nine experiments, a PLS model still provides a lot of value!

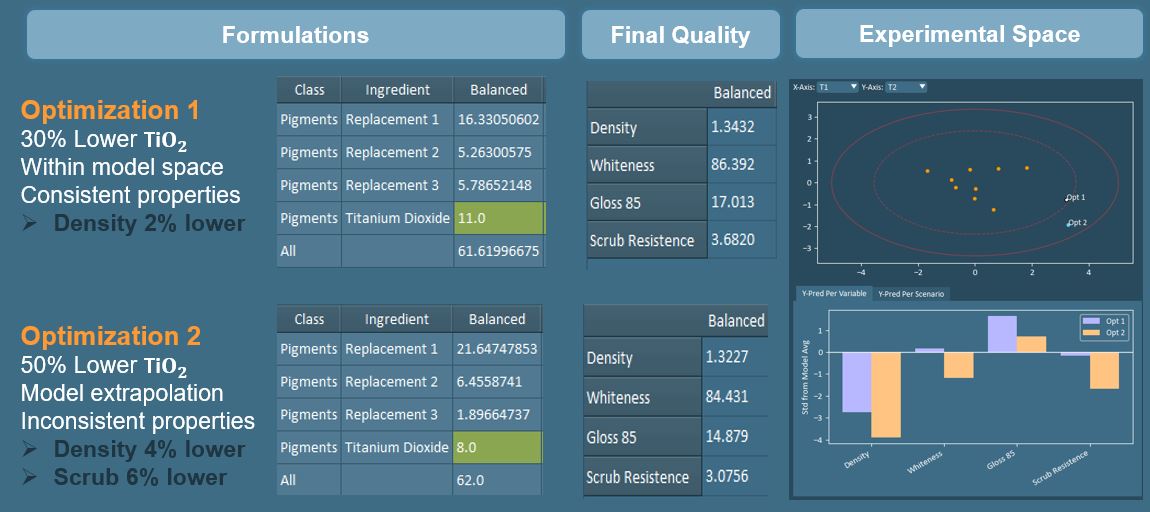

The score plot (on the left) alongside the loading plot (on the right) can be used to identify the direction of future desired experiments to lower TiO2 and their potential trade-offs. Domain experts should validate these correlations the ensure the model is modeling the expected correlations.

Simulate (Digital Experiments)

In this dataset, the lowest amount used of TiO2 was 16 wt%. Using one of the “better” observations with lower TiO2 as a starting point, FormuSense was used to simulate the impact of decreasing TiO2 further to 10 wt% using the available replacements.

As identified in modeling, reducing TiO2 lowers density. However, formulators can likely mitigate this impact by increasing the filler loading. In this case, the most important properties for assessing the TiO2 replacement were Gloss and Whiteness. These remained in the higher, desirable range while using Replacement 3.

Note that this modeling process is iterative! When a new replacement ingredient is under consideration, digital simulations can be configured to predict the impact of new ingredient combinations on the final paint properties. Next, physical experiments should be conducted to confirm the results for the most promising candidates that were identified by digital simulation. New results that have been validated by physical experiments should then be added to the model to expand the experimental design space.

Optimize (Going Backwards)

The optimization feature in FormuSense was used to back calculate a candidate formulations to achieve target properties while minimizing TiO2 wt%. The two candidates highlighted below showcase two potential experiments to run, with differing levels of extrapolation and final properties. The domain expert may make some adjustments and then run these experiments.

Replace Your TiO2 Formulations Today

Download a free 30-day trial of FormuSense today, and configure your own paint formulation scenarios using this model file.

![]() TiO2 Prediction for Architectural Paints (zipped FormuSense file)

TiO2 Prediction for Architectural Paints (zipped FormuSense file)

References

- Effects of Tio2 Partial Substitution by Various Extenders On …, www.researchgate.net/profile/Ismail-Dogan-Gunbas/publication/322050217_Effects_of_TiO2_Partial_Substitution_by_Various_Extenders_on_Architectural_Interior_Paints/links/5a40c46eaca272d294532522/Effects-of-TiO2-Partial-Substitution-by-Various-Extenders-on-Architectural-Interior-Paints.pdf.

- Meeting future coatings regulatory demands through TiO2 product design. June 9, 2023. Available at: https://www.polymerspaintcolourjournal.com/meeting-future-coatings-regulatory-demands-through-tio2-product-design/

- Staff Writer | February 27, 2020. “Pull off the Tio2 Balancing Act in Architectural Coatings.” Balance TiO2 Spacing for Better Efficiency in Architectural Coatings | Where Business Meets Science, insights.basf.com/home/article/read/pull-off-the-tio2-balancing-act-in-architectural-coatings.

- Facilitating coatings product development with Artificial Intelligence (no date) American Coatings Association. Available at: https://www.paint.org/coatingstech-magazine/articles/facilitating-coatings-product-development-with-artificial-intelligence/