There has been a sustainability shift over the past decade with more than 90% of S&P 500 companies publishing their sustainability reports.1

There has been a sustainability shift over the past decade with more than 90% of S&P 500 companies publishing their sustainability reports.1

Concrete production is one of the major challenges to tackle as it is responsible for 8% of the global carbon footprint – more than the aviation and shipping industries!1

A promising area of research relates to the use of alkali-activated concrete (AAC) in place of ordinary Portland cement concrete (OPCC). The mechanical properties of AAC are similar to OPCC, with the added potential of being more environmentally friendly. It is estimated that blended concrete could reduce CO2 emissions by approximately 13-22%.1

How much can YOU decrease CO2 emissions by?

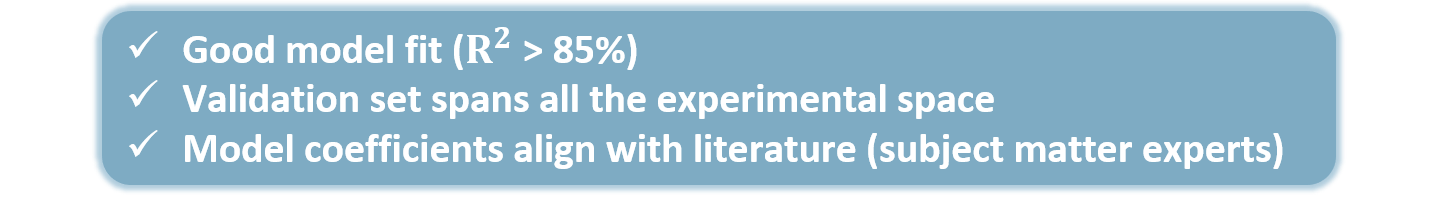

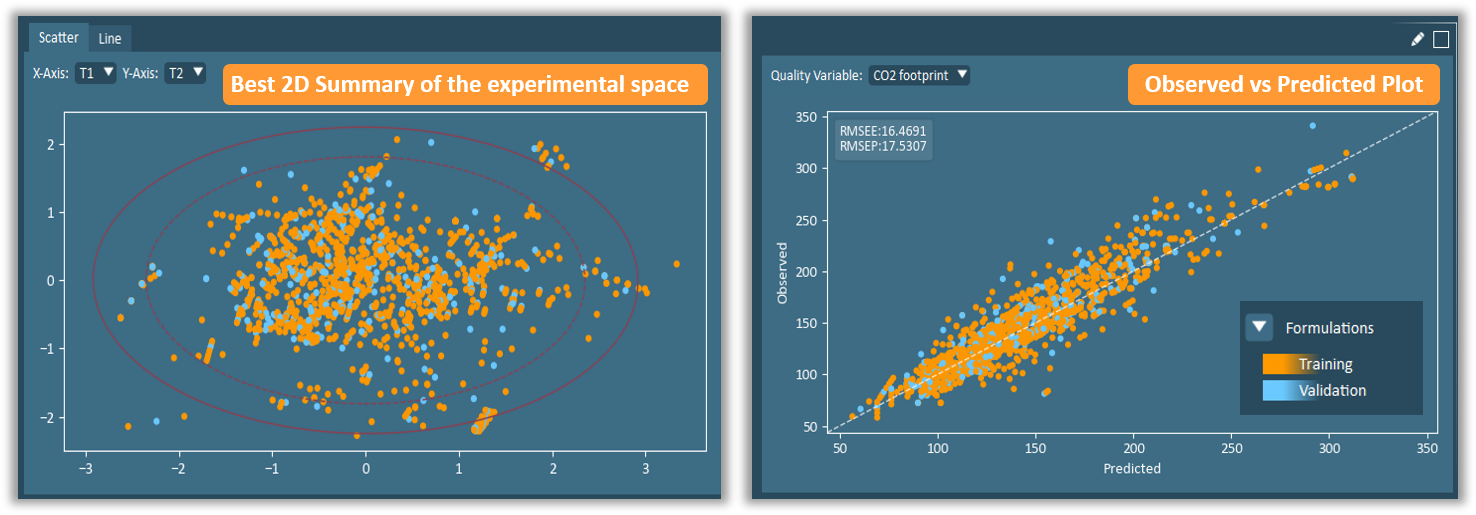

Run your own digital simulations to find out! Using a published dataset2, ProSensus has developed a predictive model with an R2 > 85% for CO2 footprint.

Download our FormuSense model file to formulate your own AAC blend and predict the CO2 footprint.

![]() CO2 Footprint Prediction for AAC (zipped FormuSense file)

CO2 Footprint Prediction for AAC (zipped FormuSense file)

New to FormuSense? Activate a free 30-day trial to access the AAC model file.

Want to see it in action first? Access a recording of the related FormuSense demo that took place on May 31, 2023 using the AAC dataset.

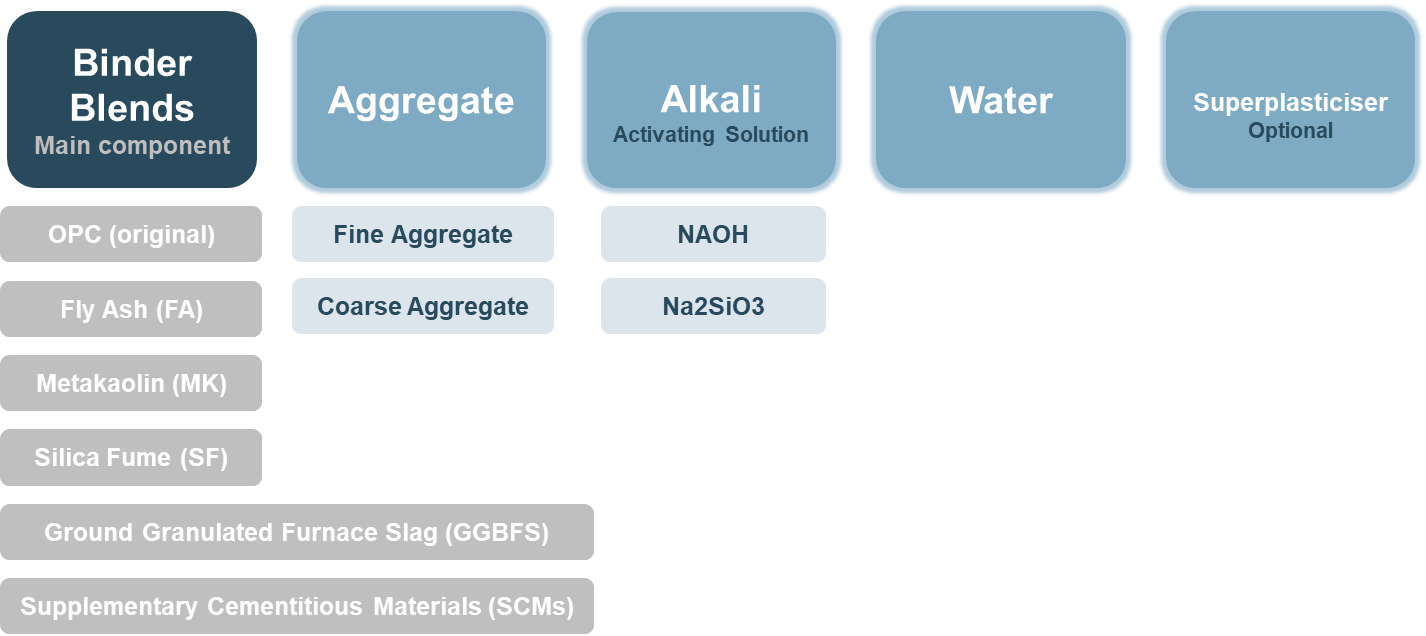

What is Blended Concrete?

Blended AAC is cement-free concrete that typically consists of the following ingredient classes and ingredients:

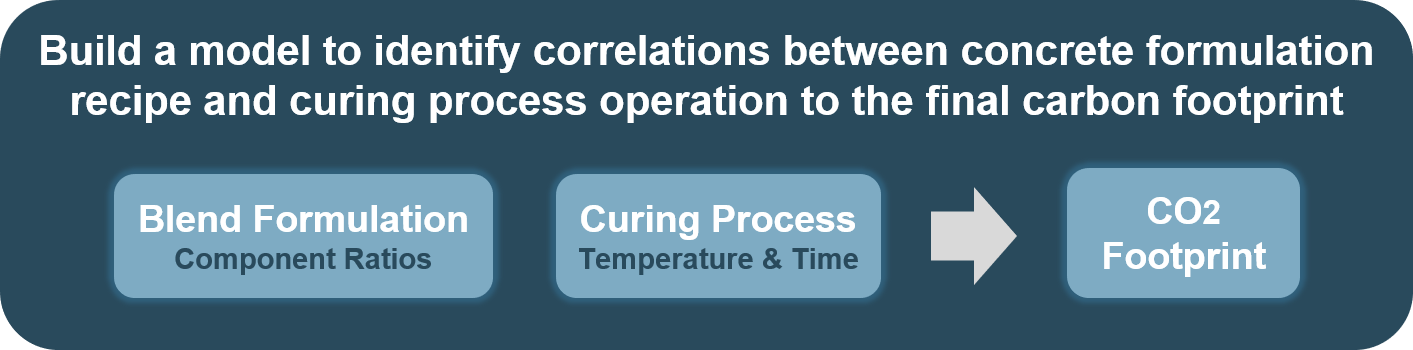

Background & Goal

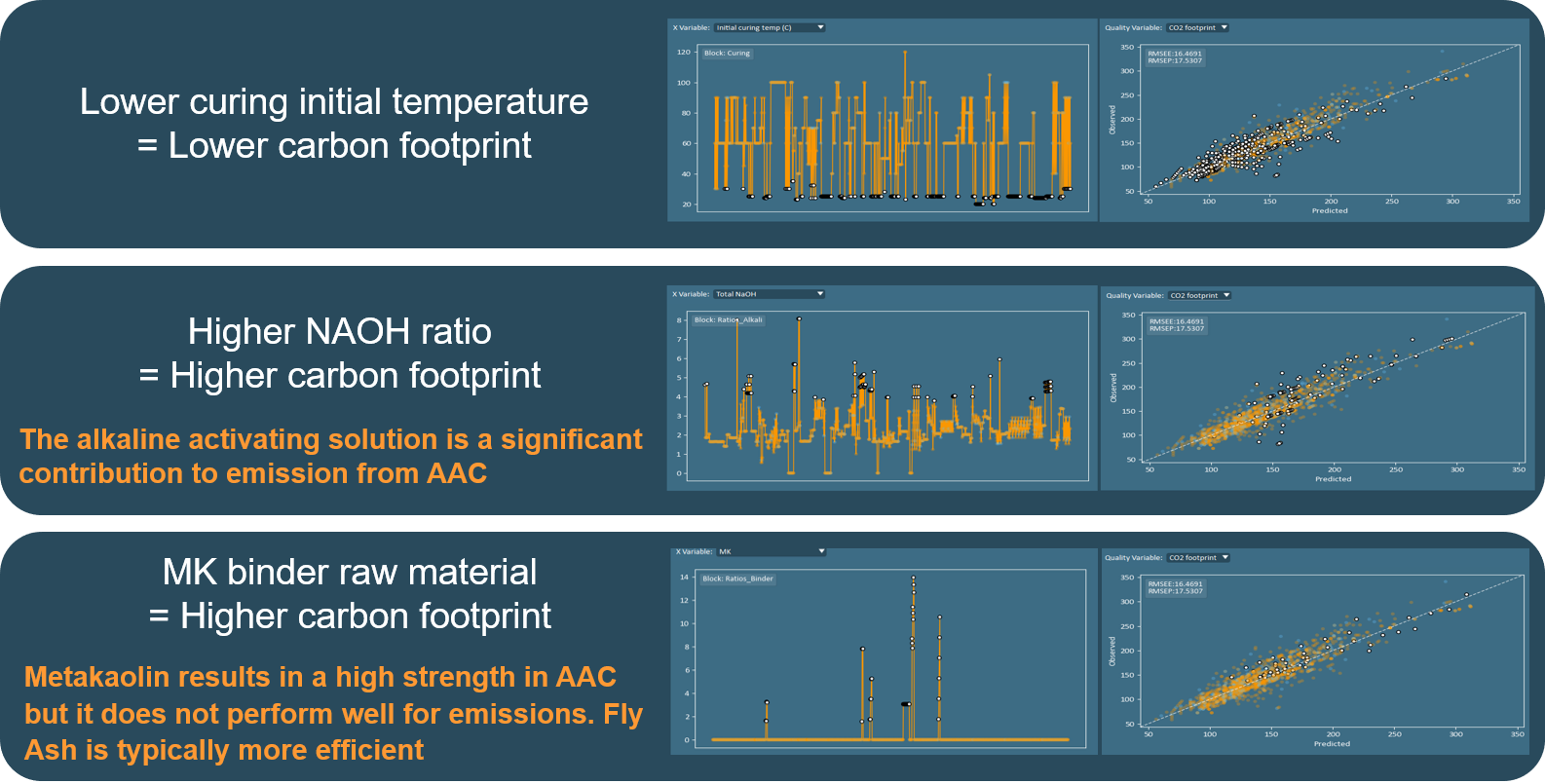

The reduction in CO2 emissions depends on several key attributes, such as blended quantity, raw material source, and curing operation.

Workflow & Results

Dataset Assembly

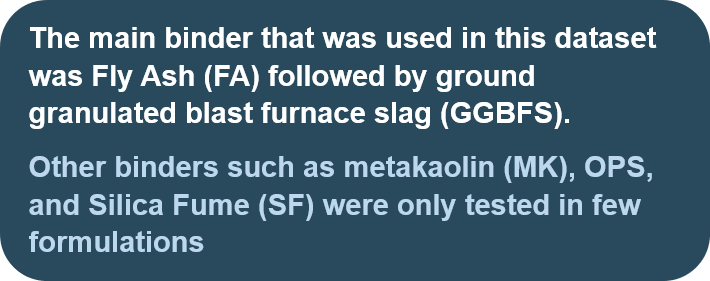

This public open-access dataset2 has ~1600 formulations (mixes) of alkali-activated concrete and corresponding CO2 footprint values. The dataset was published to facilitate the development of sustainable and environmentally friendly construction materials.

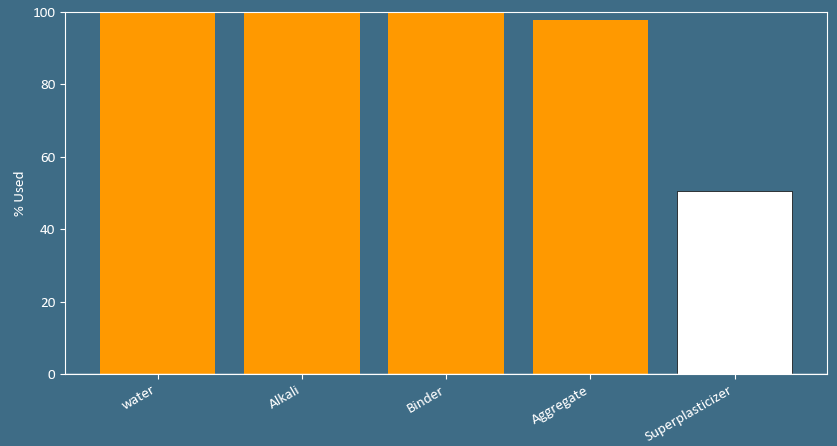

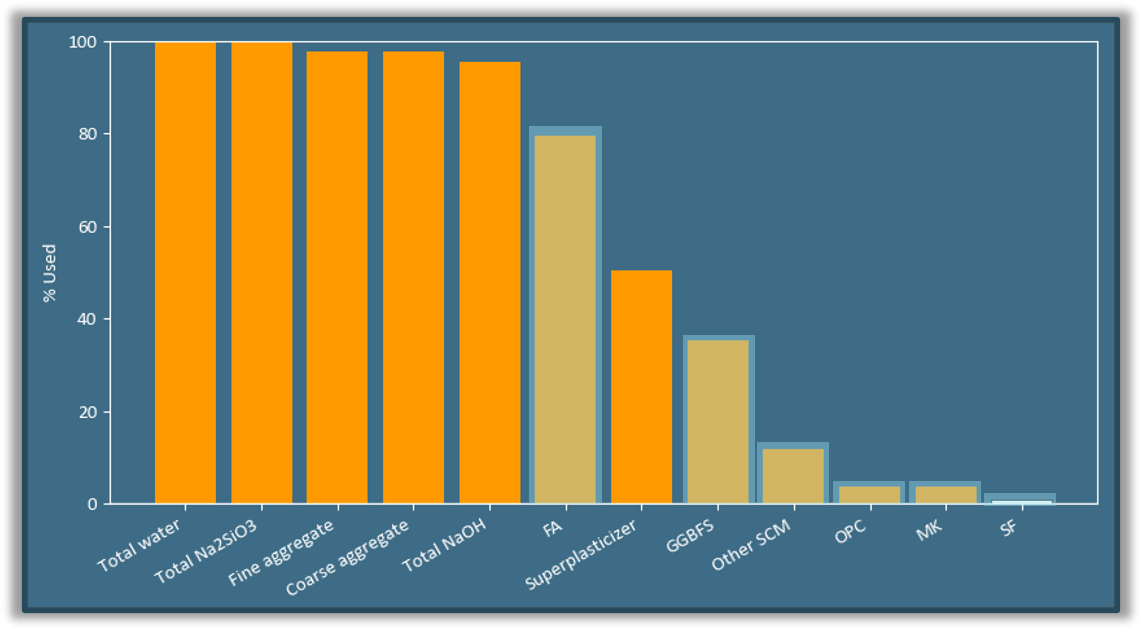

Ingredient Class Use

The analysis and results shown below were performed in FormuSense, which is very well suited for these formulations-type datasets.

The analysis and results shown below were performed in FormuSense, which is very well suited for these formulations-type datasets.

Starting off with the AAC’s main components/classes, FormuSense generates a bar plot and line plot for each ingredient class. As per the AAC expected recipe, all classes were used across all the formulations except the superplasticizer which in an optional ingredient.

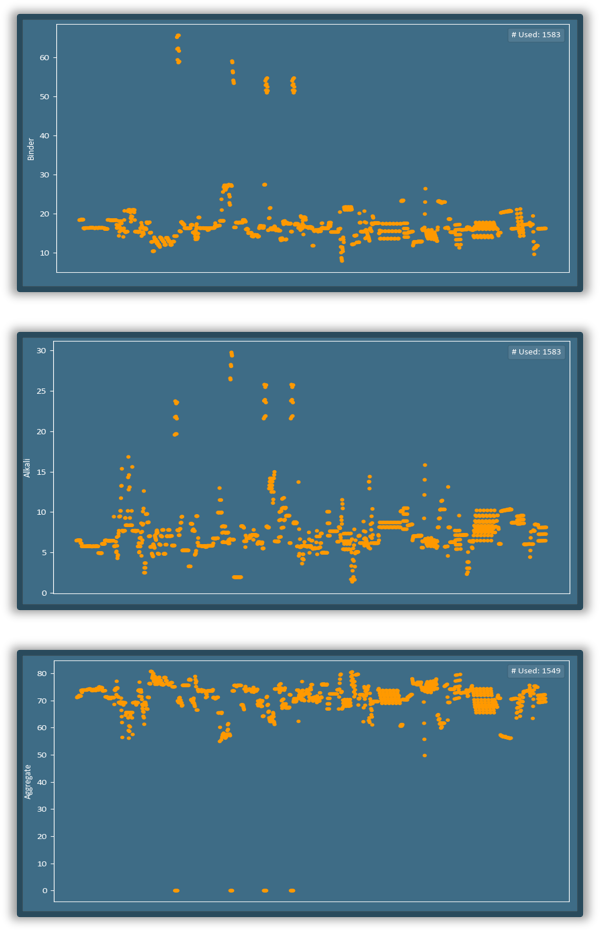

The “Binder” – main component of the AAC recipe was used in all formulations with a ratio ranging from 7% to 30% in most cases

The “Alkali”– activating solution of the AAC recipe (that releases Al and Si from base material) was used in all formulations with a ratio ranging from 1% to 30%. They are known to heavily influence the emissions of AAC

The “Aggregates” – largest component by volume (responsible for the stiffness and dimensional stability of the concrete) were used in all formulations with a ratio ranging from 55% to 80%

Ingredient Use

FormuSense also generates a summary for each ingredient to better understand the experimental space.

Model

A partial least squares (PLS) model was used to fit the variation in the dataset and identify key correlations to carbon footprint.

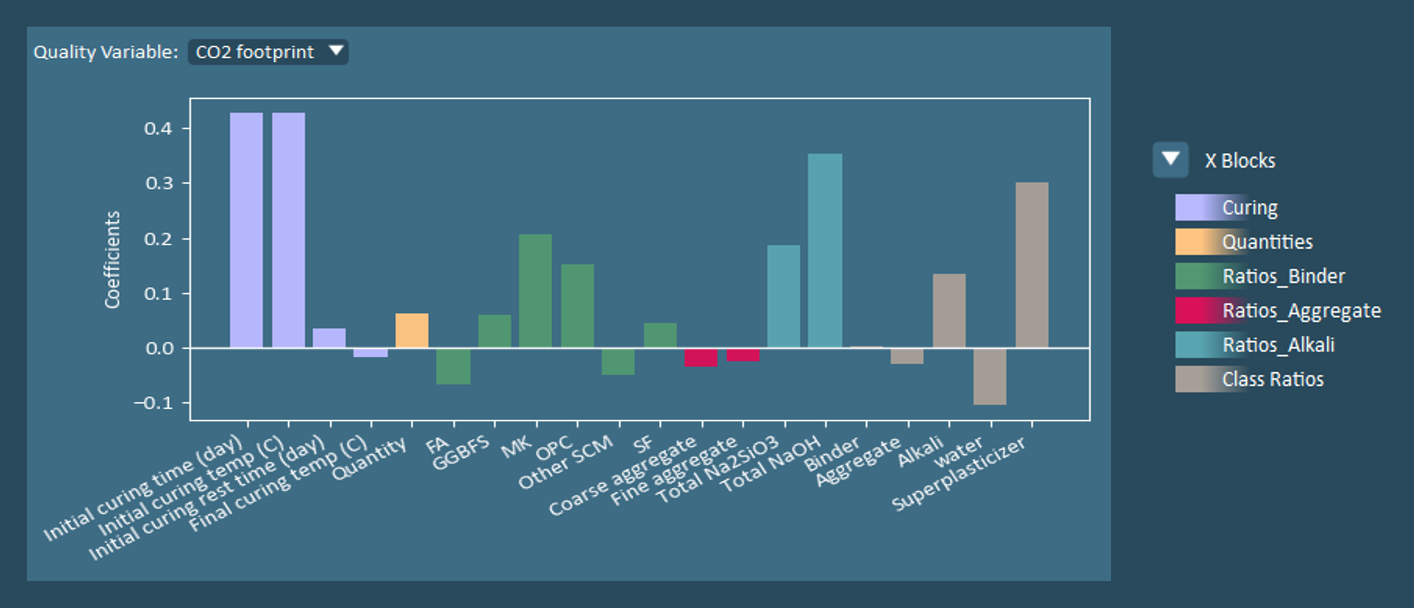

One of the most powerful plots in a PLS model for interpretation is the coefficient plot. This plot explains the simultaneous impact of all input variables on the final carbon footprint.

These coefficients aligned with subject matter expert knowledge and literature findings.

Simulate

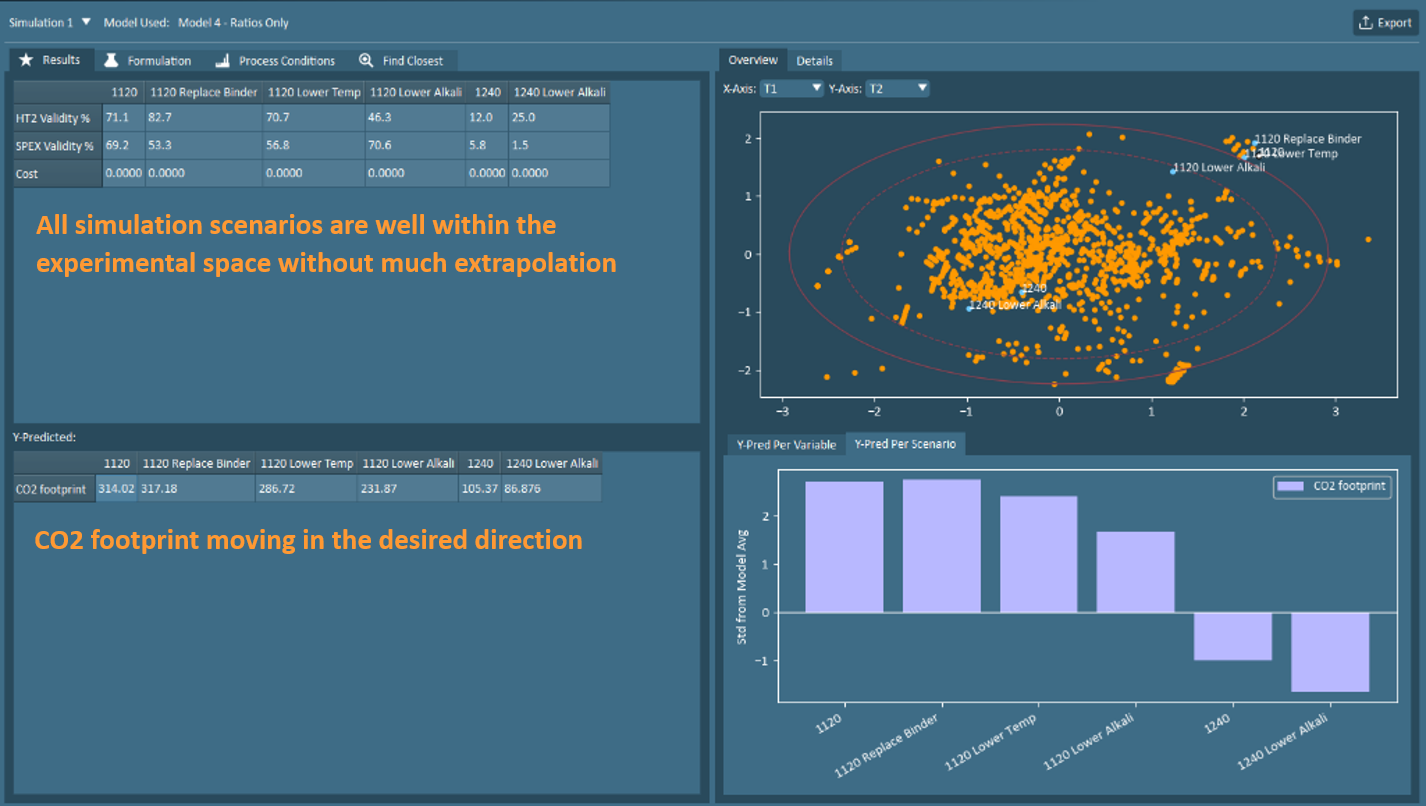

Once the results are reviewed with subject matter experts, the Simulation tool can be used to predict the outcome of new experiments with explainable AI, and ultimately reduce physical experimentation by testing all the “What if?” scenarios virtually.

In this example dataset, 6 simulation scenarios were configured, aiming to minimize the CO2 emissions within the window of acceptable mechanical properties of the blended cement.

Reduce Your Concrete CO2 Emissions Today

Download a free 30-day trial of FormuSense today, and configure your own concrete simulation scenarios using this model file.

![]() CO2 Footprint Prediction for AAC (zipped FormuSense file)

CO2 Footprint Prediction for AAC (zipped FormuSense file)

Watch the Related Demo on Demand

Request a recording of the related FormuSense demo that took place on May 31, 2023 using the AAC dataset.

References

- Ali Alsalman, Lateef N. Assi, Rahman S. Kareem, Kealy Carter, Paul Ziehl. Energy and CO2 emission assessments of alkali-activated concrete and Ordinary Portland Cement concrete: A comparative analysis of different grades of concrete. Cleaner Environmental Systems, Volume 3, 2021, 100047, ISSN 2666-7894, https://doi.org/10.1016/j.cesys.2021.100047..

- Benjami Moreno Torres, Christoph Völker, & Rafia Firdous. (2023). An Alkali-Activated Concrete Dataset for Sustainable Building Materials [Data set]. Zenodo. https://doi.org/10.5281/zenodo.7805018.